SOAP

AND DETERGENT MANUFACTURE

Md. Kaysar Hasan

Saurav

Roll: 08168; 14th Batch,

IER, DU.

Date of submission: 07 March, 2010.

CONTENT

Topic Page

1. SOAP AND DETERGENT MANUFACTURE 01

-Introduction

-The Chemistry of Soap

and Detergent Function

2. THE SOAP MANUFACTURING PROCESS 02-09

- The

Colgate-Palmolive Process

03

- The Lever Rexona

Process

06

- Laundry or 'hard'

soap manufacture 08

- Toilet soap

manufacture

09

3. THE DETERGENT MANUFACTURING PROCESS 09-11

- Detergent powder

manufacture

09

- Liquid detergent

manufacture

11

4. ANCILLIARY PROCESSES

12

- Glycerine

recovery

5. ENVIRONMENTAL IMPLICATIONS

13-14

- Synthetic

detergent biodegradability 13

- Detergent powder

14

6. ROLE OF THE LABORATORY

14-15

- Batch process soap 15

- Detergent powder

15

- Liquid detergent

15

7. REFERRENCES

15

SOAP AND

DETERGENT MANUFACTURE

Introduction

Soap is integral to our society today, and we

find it hard to imagine a time when people were kept sweet-smelling by the

action of perfume rather than soap. However, the current widespread use of soap

is only a very recent occurrence, despite the fact that it has been made for

more than 2500 years. The first recorded manufacture of soap was in 600BC, when

Pliny the Elder described its manufacture by the Phoenicians from goats tallow

and ash, and it was known among the British Celts and throughout the Roman Empire . However, these people used their soap medicinally,

and it was not until the second century AD that it was used for cleaning, and

not until the nineteenth century that it began to be commonly used in the Western

world.

Early

this century the first synthetic detergents were manufactured, and these have

now taken the place of soap for many applications. Their manufacture is covered

briefly in the second part of this article.

The Chemistry of Soap and Detergent Function

All

soaps and detergents contain a surfactant1 as their active ingredient This is

an ionic species consisting of a long, linear, non-polar ’tail’ with a cationic

or anionic ’head’ and a counter ion. The tail is water insoluble and the head

is water soluble - a difference in solubility which has two important implications.

Firstly, this makes the surfactant molecule a wetting agent: the tails migrate

to align themselves with the solid: water interface, lowering the surface

tension at that point so that it penetrates the fabric better. Secondly, it

allows the oily dirt particles to form an emulsion with the water: the tails of

many surfactant molecules surround an oily dirt particle, forming a micelle

with a drop of oil in the centre and the ionic heads of the surfactant

molecules pointing outwards and hence keeping the micelle in the polar

solution.

THE

SOAP MANUFACTURING PROCESS

The essence of soap production is the

saponification reaction:

This reaction is exothermic, and

progresses quickly and efficiently at around 125oC inside an autoclave type

reactor.

The most common fats and oils used are tallow (beef or mutton/beef

blend), coconut oil, and palm kernel oil. Different oils produce soaps of

varying hardness, odor and lathering, so the ratios of the oils used are

closely monitored to produce a blend with the most desirable characteristics

for the most reasonable cost.

However,

pure soap is hard and easily oxidized, so various additives are added to

correct this and to make a more aesthetically pleasing product. The first such

"additive" is glycerin, which is produced in the saponification

reaction. Glycerin makes the soap smoother and softer than pure soap. However,

it is also much more valuable than soap itself, so only a minimum of glycerin

is left in the soap and the remainder is extracted, purified and sold.

The glycerin is extracted from the soap with

lye2 - a brine solution that is added to the soap at the saponification stage.

Wet soap is soluble in weak brine, but separates out as the electrolyte

concentration increases. Glycerin, on the other hand, is highly soluble in

brine. Wet soap thus has quite a low electrolyte concentration and is about 30%

water (which makes it easily pump able at 70oC). To remove the glycerin, more electrolytes

are added, causing the wet soap to separate into two layers: crude soap

and a brine/glycerin mixture known as spent lye, neutral lye or sweet waters.

The soap still contains some salt, which itself functions as an additive,

altering the viscosity and color of the soap.

Once

the spent lye has been removed the soap is dried, chipped, mixed with other

additives such as perfumes and preservatives and then plodded (squeezed

together), formed into tablets and packaged for sale.

There are two different soap-making

processes used in New

Zealand

The Colgate-Palmolive Process

This is a continuous process (Figure

1) which uses a plant built by Binacchi & Co. The z process is best

understood in terms of two streams: soap flowing in the order given below against

a counter-current of lye.

Step 1 – Saponification

The raw materials are continually fed

into a reactor in fixed proportions. Assuming a production rate of 1000 kg wet

soap per hour and a 80:20 tallow: coconut oil mix, the raw materials would be

fed in at the following rates:

Coconut oil 525.9 kg hr-1

Tallow 131.5 kg hr-1

50% NaOH solution 101 kg hr-1*

*Although this is not the formula

quantity, it gives a general indication to the process condition. The actual

amount is affected by the caustic concentration in half - spent lye.

These ingredients alone would give a

low water, high glycerin soap. Soap needs to be about 30% water to be easily pumpable,

and even then needs to be held at around 70oC, so excess lye is added to

hydrate the soap and dissolve out some of the glycerin. The lye added is known

as "half spent lye" and is the lye discharged from the washing column.

This lye already contains some glycerin, but it is further enriched by that

formed in the saponification reaction.

Step 2 - Lye separation

The wet soap is pumped to a

"static separator" - a settling vessel which does not use any mechanical

action. The soap / lye mix is pumped into the tank where it separates out on

the basis of weight. The spent lye settles to the bottom from where it is piped

off to the glycerin recovery unit, while the soap rises to the top and is piped

away for further processing.

Step 3 - Soap washing

The soap still contains most of its glycerin

at this stage, and this is removed with fresh lye in a washing column. The

column has rings fixed on its inside surface. The soap solution is added near

the bottom of the column and the lye near the top. As the lye flows down the column

through the centre, a series of rotating disks keeps the soap / lye mixture

agitated between the rings. This creates enough turbulence to ensure good

mixing between the two solutions.

The rate of glycerin production is

calculated and the rate at which fresh lye is added to the washing column then

set such that the spent lye is 25 - 35 % glycerin. Glycerin is almost infinitely

soluble in brine, but at greater than 35% glycerin the lye no longer

efficiently removes glycerin from the soap.

The soap is allowed to overflow from

the top of the column and the lye ("half spent lye") is pumped away

from the bottom at a controlled rate and added to the reactor.

Step 4 - Lye separation

The lye is added at the top of the

washing column, and the soap removed from the column as overflow. As the lye is

added near the overflow pipe the washed soap is about 20% fresh lye, giving the

soap unacceptably high water and caustic levels. Separating off the lye lowers

the electrolyte levels to acceptable limits.

The soap and lye are separated in a

centrifuge, leaving a soap which is 0.5% NaCl and 0.3% NaOH, and about 31% water.

The lye removed is used as fresh lye.

Step 5 – Neutralization

Although the caustic levels are quite

low, they are still unacceptably high for toilet and laundry soap. The NaOH is

removed by reaction with a weak acid such as coconut oil (which contains

significant levels of free fatty acids), coconut oil fatty acids, citric acid

or phosphoric acid, with the choice of acid being made largely on economic

grounds.

Some preservative is also added at this

stage.

Step 6 – Drying

Finally,

the water levels must be reduced down to about 12%. This is done by heating the

soap to about 125oC under pressure (to prevent the water from boiling off while

the soap is still in the pipes) and then spraying it into an evacuated chamber

at 40 mm Hg (5.3 kPa). The latent heat of evaporation lost as the water boils

off reduces the soap temperature down to 45oC, at which temperature it solidifies

onto the chamber walls.

The soap chips are scraped off the walls

and "plodded" (i.e. squeezed together) by screws known as

"plodder worms" to form soap noodles. The soap is now known as base

or neat soap chip, and can be converted into a variety of different soaps in

the finishing stages.

The moisture evaporated off the wet soap

is transported to a barometric condenser, which recompenses the vapor without

the system losing vacuum. The moisture can contain soap dust (.Fines.) which is

removed by cyclones and returned by augers to the spray chamber, while the

water is recycled.

Base soap can also be made by a batch

process such as that used by Lever Rexona.

The Lever Rexona Process

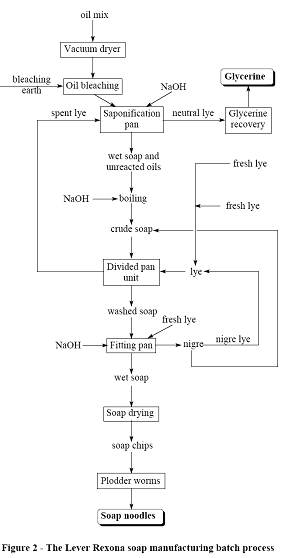

This

process is summarized in Figure 2.

Step 1 - Oil preparation

The oils used most commonly are, as in

the Colgate-Palmolive process, tallow and coconut oil. These are blended

together and dried in a vacuum chamber. Once the oils are dry, bleaching earth

is sucked by the vacuum into the chamber to remove any colored impurities. The

spent earth is land filled and the oils stored ready for saponification.

Step 2 – Saponification

The mixture of bleached oils is mixed

with spent lye from the washing stage and a caustic soda solution. The mix is

heated and then left to settle into two layers. The neutral lye (which is now rich

in glycerin) is pumped off and the mixture of soap and unreacted oils which has

risen to the top is left in the pan. More caustic liquor is added to this and

the mix reheated to saponify the remaining free oils.

Step 3 – Washing

The crude soap is then pumped to a

divided pan unit (DPU) where it is washed by a countercurrent of lye. This lye

is a mixture of fresh brine solution and nigre lye. The washed soap comes out

the far end of the DPU and is sent to the fitting pans, while the lye comes out

the near end and is pumped back into one of the saponification pans.

Step 4 – Fitting

Here the remaining unwanted glycerin is

removed from the soap by reboiling with water, NaCl and a small amount of NaOH

solution. The electrolyte concentration in the water is such that the soap and

water to separate out into two layers. The top layer is ’neat’ wet soap, which

is pumped off to be dried. The bottom layer is known as the ’nigre’ layer, and

consists of a solution of soap, glycerin and NaCl. This is left in the pan,

reboiled with further salt and left to stand, forming a soap crust over a lower

layer of nigre lye (salt and glycerin). This soap is left in the pan and is

mixed with the next intake of washed soap, while the nigre lye is pumped back to

the DPUs to wash the next batch of crude soap.

Step 5 – Drying

Moisture is flashed off under vacuum in

the same manner as was described above for the Colgate-Palmolive process.

Laundry or 'hard' soap manufacture

The base soap is mixed with color and

preservatives and milled. Perfume is then added and the mixture plodded then

extruded into a continuous bar. This, in turn, is cut into billets and stamped

out into tablets ready for packaging.

Toilet soap manufacture

Toilet soap has less water and more

fatty material (fatty acids and soap) than laundry soap. For this reason base

soap intended for toilet soap manufacture usually has extra fatty acids added

with the preservatives before it is vacuum dried. These ensure that there is no

unreacted caustic left in the soap by the time it reaches the consumer, and

also make the soap softer. Perfume, dye and pacifier are then added to the

dried soap and the mixture milled to ensure even mixing. It is then plodded and

extruded out as a continuous bar, cut into billets and stamped ready for

packaging and sale.

THE

DETERGENT MANUFACTURING PROCESS

Detergents use a synthetic surfactant

in place of the metal fatty acid salts used in soaps. They are made both in powder

and liquid form, and sold as laundry powders, hard surface cleansers, dish

washing liquids, fabric conditioners etc. Most detergents have soap in their mixture

of ingredients, but it usually functions more as a foam depressant than as a surfactant.

Detergent powder manufacture

Step 1 - Slurry making

The solid and liquid raw ingredients (Table

2) are dropped into a large tank known as a slurry mixer. As the

ingredients are added the mixture heats up as a result of two exothermic reactions:

the hydration of sodium tri-polyphosphate and the reaction between caustic soda

and linear alkylbenzenesulphonic acid. The mixture is then further heated to

85oC and stirred until it forms homogeneous slurry.

Step 2 - Spray drying

The slurry is deaerated in a vacuum

chamber and then separated by an atomizer into finely divided droplets. These

are sprayed into a column of air at 425oC, where they dry instantaneously. The

resultant powder is known as ’base powder’, and its exact treatment from this

point on depends on the product being made.

Step 3 - Post dosing

Other ingredients are now added, and

the air blown through the mixture in a fluidiser to mix them into a homogeneous

powder. Typical ingredients are listed in Table 3.

Liquid detergent manufacture

Step 1 - Soap premix

manufacture

Liquid detergent contains soap as well

as synthetic surfactants. This is usually made first as a premix, and then

other ingredients are blended into it. This step simply consists of neutralizing

fatty acids (rather than fats themselves) with either caustic soda (NaOH) or

potassium hydroxide.

Step 2 - Ingredient

mixing

All ingredients except enzymes are

added and mixed at high temperature. The ingredients used in liquid detergent

manufacture are typically sodium tri-polyphosphate, caustic soda, sulphonic

acid, perfume and water. The functions of these ingredients have been covered above.

Step 3 - Enzyme addition

The mixture is cooled and milled, and

the enzymes added in powder form.

ANCILLIARY PROCESSES

Glycerin recovery

As has already been stated, glycerin is

more valuable than the soap itself, and so as much of it as possible is

extracted from the soap. This is done in a three step process.

Step 1 - Soap removal

The spent lye contains a small quantity

of dissolved soap which must be removed before the evaporation process. This is

done by treating the spent lye with ferrous chloride. However, if any hydroxide

ions remain the ferrous ions react with them instead, so these are first removed

with hydrochloric acid:

HCl + NaOH →

NaCl + H2O

The ferrous chloride is then added.

This reacts with the soap to form an insoluble ferrous soap:

FeCl2 +

2RCOONa → 2NaCl + (RCOO) 2Fe

This precipitate is filtered out and

then any excess ferrous chloride removed with caustic:

2NaOH + FeCl2

→ Fe (OH)2 (s) + 2NaCl

This is filtered out, leaving a

soap-free lye solution.

Step 2 - Salt removal

Water is removed from the lye in a

vacuum evaporator, causing the salt to crystallize out as the solution becomes

supersaturated. This is removed in a centrifuge, dissolved in hot water and

stored for use as fresh lye. When the glycerin content of the solution reaches

80 - 85%, it is pumped to the crude settling tank where more salt separates

out.

Step 3 - Glycerin

purification

A small amount of caustic soda is added

to the crude glycerin and the solution then distilled under vacuum in a heated

still. Two fractions are taken off - one of pure glycerin and water. The glycerin

thus extracted is bleached with carbon black then transferred to drums for

sale, while the water/glycerin fraction is mixed with the incoming spent lye and

repeats the treatment cycle.

ENVIRONMENTAL IMPLICATIONS

Soap is designed as a product to be used

once then flushed down the drain, so as expected the environmental implications

of its manufacture are not nearly as great as many other chemical processes.

There are two main areas of concern: the safe transport and containment of the raw

materials and the minimization of losses during manufacture.

The three main components of soap by both cost

and volume are oils, caustic and perfumes. Oils and perfume are immiscible in

water and if spilled create havoc, although the oils do solidify at room

temperature. Transport of these products is by trained carriers, and the systems

for pumping from the truck to storage tanks are carefully designed. Perfumes

are bought in lined steel drums which are quite robust, and flammable perfumes

are not used in soaps.

All storage tanks are surrounded by bunds to

catch the contents of a tank should it rupture or a valve fail. When the

storage system is designed, all the safety features (such as access to tank and

valves) are designed in, as well as procedures to deal with the product should

it end up in the bounded area.

Within the plant, all the process areas are

also bounded, and the trade waste from there piped to an interception tank

before draining to the council’s trade waste system. The contents of the

interception tank are continuously monitored for acidity or alkalinity, and are

designed to settle out excess solids or light phase chemicals. If a spill is

detected in the plant itself, a portion of the interception tank can be

isolated off and the effects of the spill neutralized before the waste is

dumped.

In most cases, however, potential problems are

identified and stopped before they happen. Often an off-spec product can be

reprocessed and blended rather than dumped, and even washout water can be

reprocessed to minimize the discharges from the plant.

Finally,

the manufacturing process itself is closely monitored to ensure any losses are

kept to a minimum. Continuous measurements of key properties such as

electrolyte levels and moisture both ensure that the final product is being

made to spec, and ensures the manufacturing process is working as it was

designed to. Hence the losses in the plant will indirectly be minimized because

the process itself is being monitored.

Synthetic detergent biodegradability

There has recently been a strong move away

from the environmentally hazardous biologically stable detergents used in the

past to biodegradable ones. The sulphonic acid and nonionic detergents used in New Zealand New Zealand

Detergent powder

Detergent

powder manufacture has some specific environmental issues associated with it

that are not present in other areas of the industry. These are dust control and

volatile organic emissions. Dust present during delivery and transfer of bulk

powdered detergent (and powdered raw materials) is a potential problem. Dry and

wet cyclones are used to filter out most of the dust, and all emissions are

monitored. If the dust level in these does exceed acceptable limits,

appropriate remedial action is taken. Dust levels in emissions must be kept below

50 mg m-3.

The spray drying tower also releases volatile

organics. These emissions are minimized by having tight specifications on what

can be added as primary detergent active material. Any potentially hazardous

material is added with the secondary actives after the tower so that it is not

heated. Spot checks are done on the total hydrocarbon content of the exhaust

gases using a flame ionization detector.

ROLE OF THE LABORATORY

The

laboratory monitors the formulation and specification of products from raw

material to finished goods. Much soap is formulated locally, and the laboratory

tests a range of formulations for stability and manufacturing practicality. The

trial formulations are aged in a warm oven to simulate a couple of years of

shelf life, and then checked for perfume loss or alteration, base odor, color

stability and any general rancidity. Formulations are also constantly checked

for cost effectiveness, and soaps are frequently reformulated for cost and supplier

considerations.

When a new formula has been agreed the

laboratory will lay down the specifications that the finished soap and its

intermediary stages must meet. These could be color, odor, moisture or

electrolyte concentrations, or the concentrations of impurities or additives.

These specifications are also constantly being revised as the production

equipment is improved, or consumer demands change.

The laboratory lays down all the

specifications for raw materials to be purchased against. These specifications

become the basis for the supplier to quote against. The materials are constantly

tested against these specifications, either on a shipment basis or supplier’s

batch size. In some cases the manufacturing plant is inspected and approved,

and if the supplier can validate their process then the need for many routine

or expensive tests can be reduced or eliminated.

In most cases quality testing is performed at

the process, by the process operators. The laboratory hold samples of every

batch of finished goods for twelve months, so that if there are any consumer

complaints, an original sample can be tested against the defect sample to determine

the cause of the complaint.

Tests carried out on some particular

products are listed below.

Batch process soap

The incoming tallow and coconut oil are tested

for colour (after bleaching) and free fatty acid content. The neat liquid soap

is tested for free alkali, salt content and glycerol content, while the soap

chips are tested to moisture and fatty acid content.

Detergent powder

On-line tests are continuously carried

out on density and moisture. The laboratory also tests for the concentrations

of active detergent, sodium tri-polyphosphate, moisture, soda ash, enzymes and

bleach, and monitors physical properties such as dynamic flow rate, compressibility,

particle size, color and perfume.

Liquid detergent

The product is typically tested for

viscosity, pH, cationic detergent (fabric conditioner)

content,

enzyme content, conductivity (a measure of detergent stability), color and

perfume.

REFERRENCES

•

The Enclyclopædia Britannica (15th ed.); Encyclopædia Britannica,

Inc.; 1979

• Selinger, Ben; Chemistry in the

Marketplace (3rd ed.); Harcourt Brace Jovanovich;

1986

very good knowledge.

ReplyDelete